- Home Page

- Company Profile

-

Our Products

- Linear Motion Guide

- PMI Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

- V Line Linear Guideway System

- INA Linear Guide Way

- Rexroth Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

- NSK Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

- THK Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

- IKO Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

- Schneeberger Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

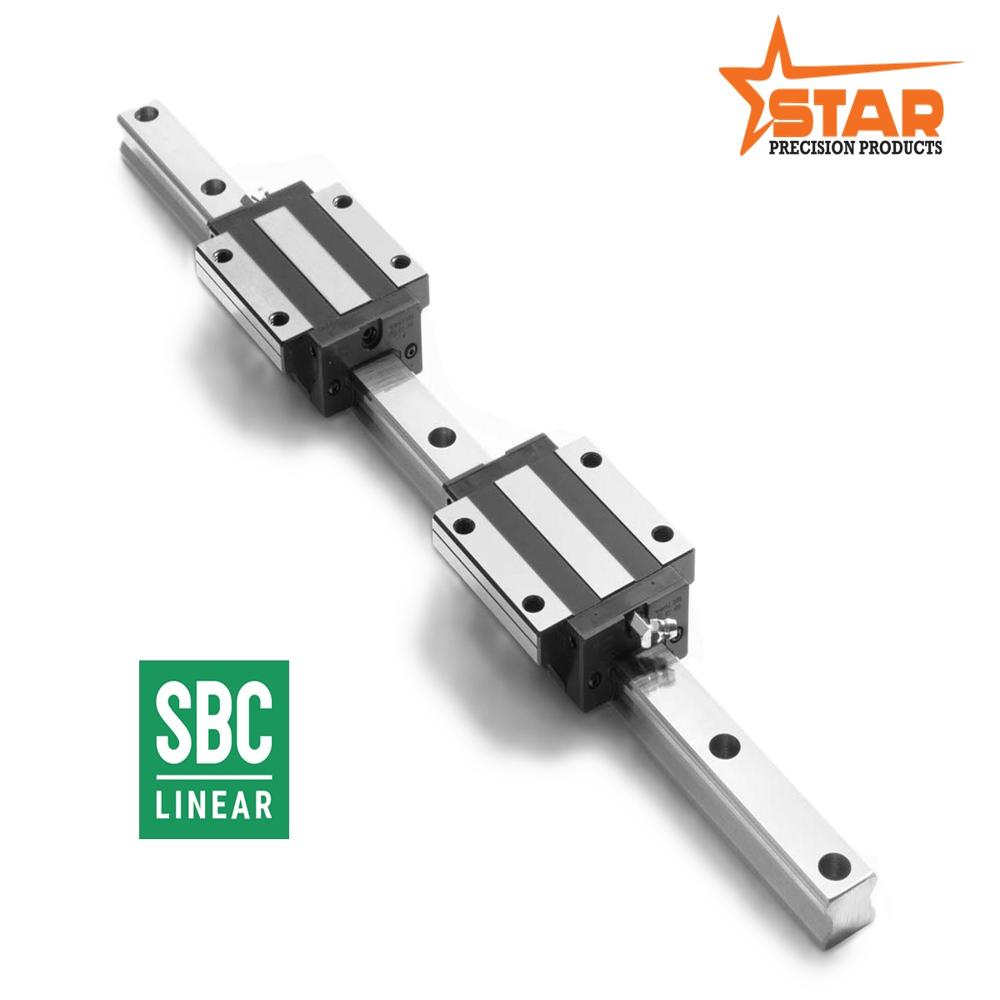

- SBC Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

- Thomson Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

- GMT V Type Cross Roller Guide Ways

- Staf Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

- RNG Type Schneeberger Linear Bearings

- Rexroth Roundway Roller Bearings

- Thomson Roundway Roller Bearings

- Speed Linear Guide

- Misumi Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

- Rosa Cross Roller Cage

- Eigis V- Guide Flat Cage Assemblies

- Hiwin Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

- Industrial Grease And Gun

- THK AFB-LF Lithium Grease

- THK AFC Grease For High Speed And Micro Vibration

- THK AFG High Grade Grease for Ball Screws

- THK AFA Grease

- THK AFE Grease

- THK AFJ Grease for Ball screws

- NSK LGU Grease

- NSK LR3 Grease

- NSK AS2 Grease

- NSK NF2 Grease

- NSK LG2 Grease

- NSK NS7 Grease

- NSK NSL Grease

- THK AFF Grease For Clean Room Application

- NSK PS2 Grease

- THK Grease Gun Unit

- Linear Bushes - Block and Shaft Support

- NB Linear Bush

- Shaft Support Blocks

- Samick Open Type LM Block

- INA Close Type LM Block

- Misumi Pilot Flanged Type Linear Bushing

- Round Flanged Type Linear Bushing

- Nippon Adjustable Type (AJ) Linear Ball Bushing

- IKO Rotary Stroke Bushing

- THK Open Type Linear Ball Bushing

- Thomson Super Smart Ball Bushing

- Hard Chrome Plated Shaft

- Aluminum Shaft Support Rails

- End Support Blocks

- THK Oval Flange Linear Bushing

- Rexroth Square Flanged Type Linear Bushing

- Middle Pilot Flanged Type Linear Bushing

- Industrial Bearings

- Stainless Steel Bearing

- Needle Roller Cage Assemblies

- IKO Rod End Bearing

- Nadella Bearing

- L Joint Bearings

- RHP Ball Screw Support Bearing

- NSK Spindle Bearing

- Cyclo Drive Bearing

- Bearings For Wind Turbine Planetary Gearbox

- INA ZKLF Bearings For Screw Drives

- Air Bearing Spindles

- Four Row Cylindrical Roller Bearings

- Rollon Linear

- Track Roller Bearings And Cam Followers

- End Supports Unit For Ball Screw

- Combined Bearing

- WD Make Combined Bearings

- Couplings And Locking Elements

- Ball Screws

- Wire Straightening Roller

- Zimmer Locking Clamping And Braking Elements

- One Way Cam Clutch And Bearing

- Crossed Roller Bearing

- Plastic Bearings

- Ball Splines And Shaft

- Zimmer Shock Absorbers

- Hex And Square Bore Bearings

- Slewing Bearings

- Yinsh Precision Lock Nut

- High Temperature Bearing

- Ball Cage

- Needle Roller Bearing

- Rod Ends

- Rack And Pinion Gear

- Cylindrical Roller Bearings

- Linear Motion Guide

- Contact Us

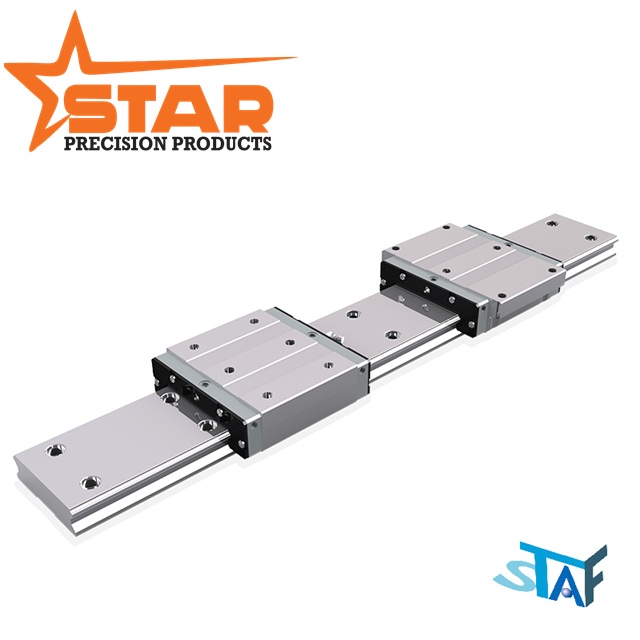

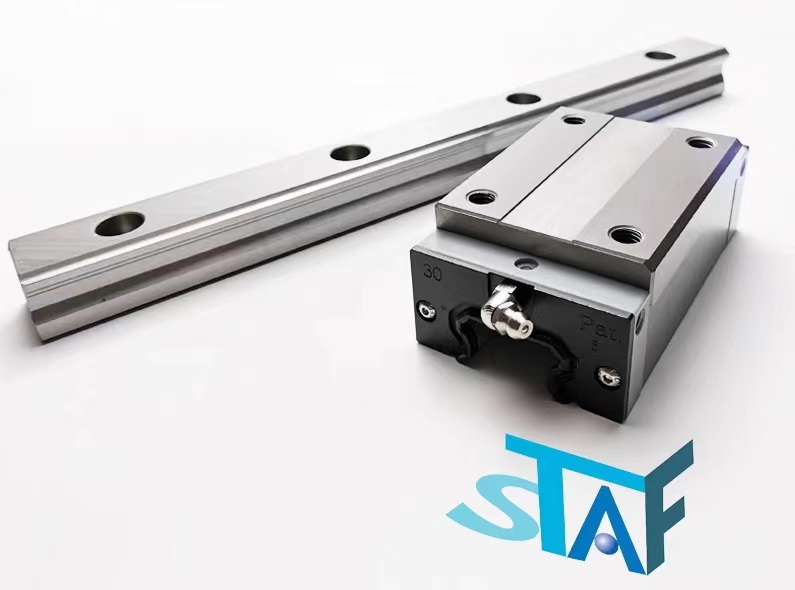

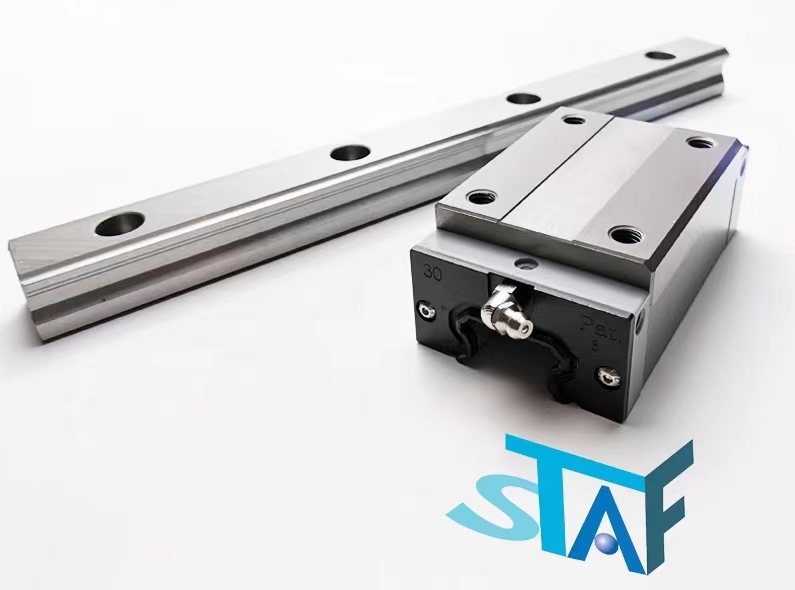

Staf Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail

2500.0 INR/Unit

Product Details:

- Machine Type CNC / VMC Machines

- Accuracy 0.015 mm

- Surface Treatment Optional

- Technology Linear Motion Technology

- Features Linear motion is one-dimensional motion along a straight line

- Usage Industrial

- Type Linear Motion

- Click to View more

X

Staf Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail Price And Quantity

- 2500.0 INR/Unit

- 1 Unit

Staf Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail Product Specifications

- Linear Movement

- Linear Motion

- Industrial

- Carbon Steel

- 1 Kilograms (kg)

- Staf Linear Guide Way

- Linear motion is one-dimensional motion along a straight line

- 15 Millimeter (mm)

- Linear Motion Technology

- 15 Millimeter (mm)

- 0.015 mm

- CNC / VMC Machines

- Different Size Are Available

- 4 Meter (m)

- Horizontal / Vertical Movement

- Silver

- Optional

Staf Linear Guide Ways / Linear Guide / Linear Motion Guide / LM Guide / Linear Rail Trade Information

- Chennai

- Cash in Advance (CID)

- 100 Unit Per Month

- 1 Days

- Yes

- Contact us for information regarding our sample policy

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

STAF Linear Guide Ways Precision Motion for Modern Industry

Introduction to STAF Linear Guide Ways

STAF Linear Guide Ways, also known as LM Guides, linear rails, or linear motion guides, are world-renowned for their high precision, durability, and smooth motion. Founded in Taiwan, STAF has been a leading provider of linear motion systems for industries including CNC machines, robotics, semiconductor equipment, automation, and medical devices. Their guide systems are engineered for high-accuracy, low-friction, and high-rigidity applications, making them a preferred choice for precision engineering.

Keywords: STAF Linear Guide Way, LM Guide, Linear Rail, Linear Motion Guide, Precision Linear Guide.

What is a STAF Linear Guide Way?

A STAF Linear Guide Way is a mechanical system that allows smooth, low-friction linear movement along a path. The system generally consists of:

-

Linear Rail (Way): The stationary track providing a straight path for the motion.

-

LM Block (Carriage): The moving element carrying the load.

-

Recirculating Balls or Rollers: Enable continuous, smooth motion with minimal friction.

STAF guide ways are designed for maximum accuracy, long service life, and high load capacities, making them ideal for high-precision CNC machining, robotics, and automated manufacturing systems.

Key Features of STAF Linear Guide Ways

-

High Load Capacity and Rigidity: STAFs profile rail guides distribute load efficiently, allowing the system to handle heavy weights and high thrusts in multiple directions.

-

Exceptional Precision: Minimal clearance and optimized raceway design ensure micron-level accuracy for CNC machines, robotics, and semiconductor handling.

-

Low Friction Operation: Recirculating balls or rollers reduce energy loss, wear, and noise, improving efficiency and longevity.

-

Durability and Longevity: Engineered with hardened steel or stainless steel components for long service life, even in demanding industrial environments.

-

Error Absorption: Can compensate for minor installation misalignments, ensuring consistent precision in challenging setups.

Keywords: High-accuracy linear rail, precision linear guide, linear bearing rail, CNC linear guide, profile rail guide.

Types of STAF Linear Guide Ways

-

Ball-Type Linear Guide Way: Smooth and fast movement with moderate rigidity.

-

Roller-Type Linear Guide Way: High rigidity and load capacity for heavy-duty applications.

-

Caged Ball Linear Guides: Reduce noise and friction at high speeds.

-

Full-Roller Linear Guides: Ideal for ultra-high precision and rigidity applications.

-

Special Environment Models: Designed for cleanrooms, high-temperature areas, or corrosive environments.

-

Linear Guides with Integrated Encoders: Provide precise positional feedback for CNC machines, automation, and robotics.

Applications of STAF Linear Guide Ways

-

CNC Machines: STAF Linear Guides enable high-speed, precise cutting, milling, and drilling operations.

-

Robotics: Smooth and repeatable motion for robotic arms, pick-and-place systems, and automation.

-

Automation & Material Handling: Conveyors, assembly lines, and packaging systems benefit from linear precision and smooth operation.

-

Semiconductor Industry: Micron-level positioning for wafer handling, lithography, and precision assembly.

-

Medical Devices: MRI machines, surgical robots, and diagnostic equipment require precise linear motion.

-

Industrial Machinery: High-load and high-rigidity applications in manufacturing, automation, and testing setups.

Keywords: STAF Linear Guide Way, LM Guide, linear rail, precision linear guide, profile rail guide.

Material and Construction of STAF Linear Guides

STAF Linear Guides are made from high-quality steel, stainless steel, or special alloys, with options for hardened surfaces and protective coatings. The balls and rollers are precision-ground and hardened to ensure smooth motion and long service life.

-

LM Block (Carriage): Hardened steel with precision-ground raceways.

-

Recirculating Balls/Rollers: High-hardness steel or stainless steel; optional ceramic balls for ultra-precision.

-

Rail (Way): Precision-ground and hardened steel, sometimes stainless steel for corrosion resistance.

Surface treatments include chrome plating, nickel coating, and lubrication embedded coatings to reduce wear and friction.

Why Choose STAF Linear Guide Ways?

-

Taiwanese Precision Engineering: Trusted for decades in high-accuracy machinery worldwide.

-

Durability and Reliability: High load capacity and resistance to wear for long-lasting performance.

-

Versatility: Wide range of types and sizes to suit any industrial application.

-

Energy Efficiency: Low-friction design reduces operational energy consumption.

-

Low Maintenance: Minimal wear and long service life reduce downtime and maintenance costs.

-

Conclusion

STAF Linear Guide Ways are ideal for industries demanding precision, rigidity, and low-friction linear motion. From CNC machining to robotics, automation, and medical devices, STAF LM Guides provide reliable, long-lasting performance.

For companies seeking high-precision linear solutions, STAF offers ball-type, roller-type, and specialized guides, ensuring the right fit for any application.

Call to Action:

-

Browse our STAF Linear Guide catalog for LM Guides, linear rails, and profile rail guides.

-

Contact us a trusted STAF supplier for technical support, selection guidance, and custom solutions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Linear Motion Guide' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese